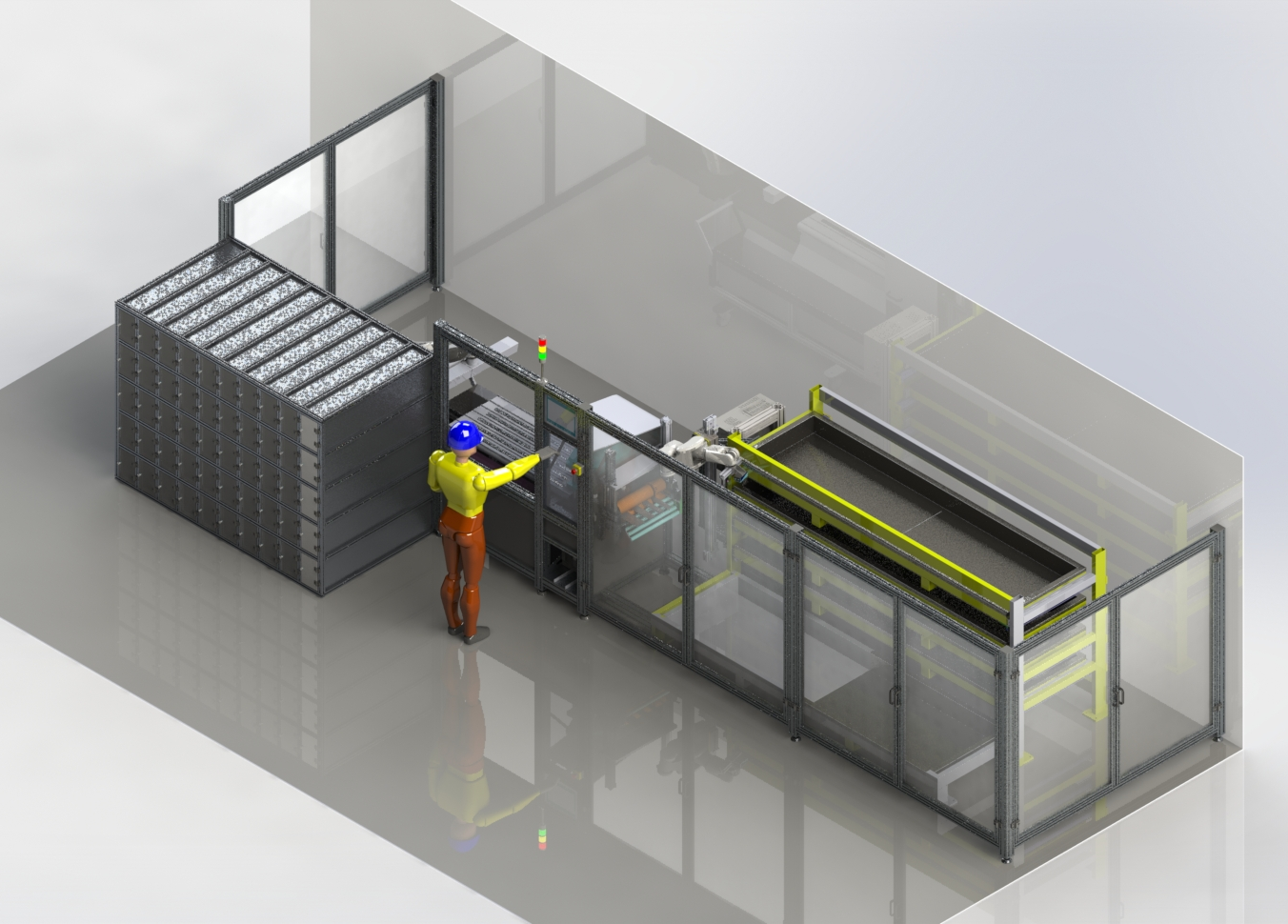

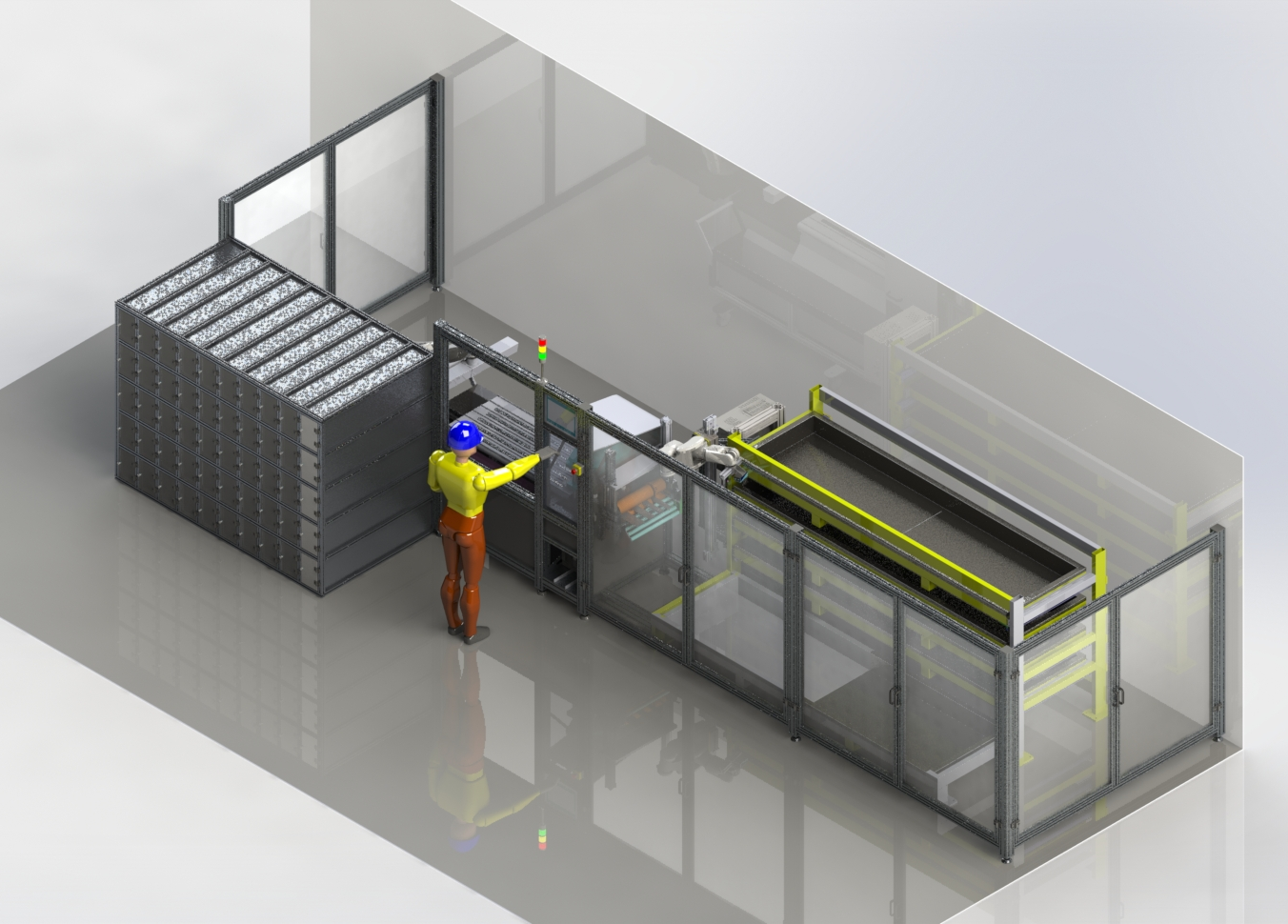

Automation system for cutting and preparing inventory of aluminum profiles

Client:

ACP Air Conditioning Accessories

Solutions:

- Development, design, production, integration (FULL TURNKEY) of an automation machine with full flexibility in size and quantity.

- The system has intelligent sensing and control that includes collecting, monitoring and analyzing the information on the machine’s performance.

Disciplines Used:

- Mechanical Engineering

- Software Engineering

- Electronic Engineering

- Industrial Control

Challenges:

- The cutting stage in the production of frames (grills) for return air of office air conditioning systems is done completely manually.

- The process Requires staffing 2 full-time positions.

Project KPI’s:

- Engineering complexity: 9/10

- Schedule: 5/10

- Budget: 7/10

- Operational efficiency: 300%

Implementation:

Client:

ACP Air Conditioning Accessories

Challenges:

- The cutting stage in the production of frames (grills) for return air of office air conditioning systems is done completely manually.

- The process Requires staffing 2 full-time positions.

Solutions:

- Development, design, production, integration (FULL TURNKEY) of an automation machine with full flexibility in size and quantity.

- The system has intelligent sensing and control that includes collecting, monitoring and analyzing the information on the machine’s performance.

Project KPI’s:

- Engineering complexity: 9/10

- Schedule: 5/10

- Budget: 7/10

- Operational efficiency: 300%

Disciplines Used:

- Mechanical Engineering

- Software Engineering

- Electronic Engineering

- Industrial Control

Implementation:

Ready to start the project?

Already have a brilliant idea?

We will be happy to make an appointment with you and hear the details of the idea.

Please leave contact details and we will get back to you soon.